160 Years of

American Manufacturing

When the Pendleton Woolen Mill opened in 1909, it was one of more than a thousand in the United States. Today, Pendleton owns and operates two of the few remaining woolen mills. With more than a century of manufacturing, a Pendleton product carries the spirit of the West.

Pacific

Northwest

Mills

Our jacquard-patterned fabrics and blankets are woven at our original mill in Pendleton, Oregon, home to the world-famous Pendleton Round-Up. This mill started weaving trade blankets in 1909.

Iconic Designs

Our signature plaid, stripe and solid-colored fabrics are woven at our mills that have been in operation for over 110 years. These enduring fabrics are woven on our state-of-the-art looms, allowing us to produce the quality-crafted blankets and fabrics Pendleton is known for today.

American

Craftsmanship

RAW MATERIALS

Pendleton has long-standing relationships with wool growers. We choose only the highest quality 100% pure virgin wool, selected for fineness, crimp, length, strength and color. We source our wool from around the world as well as locally, including from 5th generation family sheep ranchers neighboring our Pendleton, Oregon mill.

PREPARING THE WOOL: SCOURING + DYEING

Wool passes gently through a duster and a series of baths and squeeze rolls to remove water, dirt and lanolin. It is then dried and packed into bales. It may be dyed as fibers, yarn or fabric. Dyes are circulated by pumps, as computers read sample colors. Temperature and pressure are controlled to produce rich, permanent color.

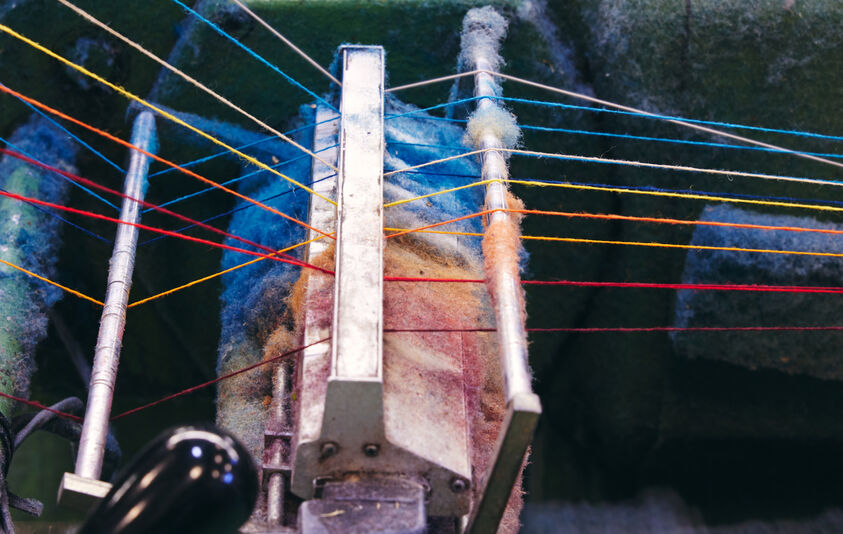

MAKING YARNS: CARDING + SPINNING

Wool fibers are carded into a fine web and then divided into thin strands called roving, which is smoothed, aligned for uniformity, and wound onto large spools for spinning. Spools of roving are mounted on the spinning frame and delivered to a bobbin, where twist is introduced to give strength to yarn. One pound of wool can make ten miles of spun yarn.

WEAVING

Using state-of-the-art looms, lengthwise (warp) and crosswise (weft) yarns are interwoven at right angles to form fabric. Pendleton’s looms can produce 300 yards of 80-inch shirt fabric in one day.

HAND FINISHING

Woolen fabric is subjected to controlled heat, moisture, friction and pressure to produce softer, more compact fabric in a process called “fulling.” Napping with a fine wire brush creates a soft, fuzzy surface, while shearing the cloth produces a smooth, even surface. Our sewers then add labels, and all fringe is hand-cut. Each blanket and piece of fabric is carefully inspected and finished by hand to ensure the highest or quality.